rockwell hardness test blocks brass|hra vs hrc : purchaser The previous NIST investigations examined how much a 9 mm thick test block will bend due to repeated indentations and how the bending affects the measurement results. That examination was made by performing Rockwell B hardness tests over the surface of a brass test block, and periodically measuring the flatness of the block’s bottom surface. WEB17 de set. de 2021 · 第2季第10集 今夜为科里干杯. 这篇剧评可能有剧透. 有人评价科里是最腹黑的老板,最现实的野心家,最失败的改革者,甚至表白都选了最烂的时机,没错,都对,但这就是科里艾利森,要么冲锋陷阵,要么倒在冲锋陷阵的路上。. 我看得见你事业受挫的 .

{plog:ftitle_list}

Programação ESPN Quinta 29 de fevereiro. 06:00 SportsCenter Fique por dentro dos principais fatos e imagens que marcaram o dia do noticiário esportivo, com temas fundamentais e polêmicos, informações apuradas e opiniões transparentes, sem abrir mão do bom humor. 07:00 .

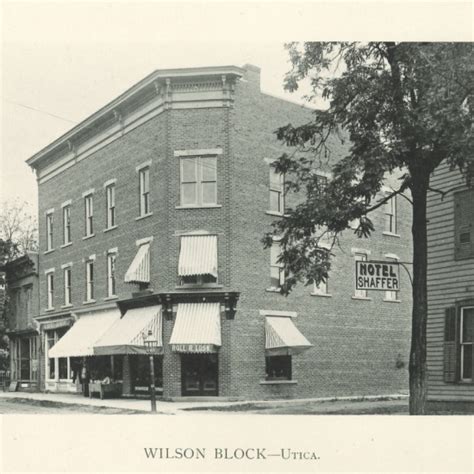

wilson block

does hard candy test on animals 2014

westport hardness blocks

Phase II offers a vast array of different hardness test blocks for Rockwell, Brinell and Vickers scales, as well as Portable hardness testers; Phase II hardness test blocks are made of high grade materials to insure unmatched accuracy and repeatability throughout the entire block.Test hardness right on your production floor. Unlike benchtop testers, these portable ones don’t require you to move large or hard-to-access parts. They use an indenter to measure the .Brinell hardness of cartridge brass – UNS C26000 is approximately 100 MPa. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the .

Calibrated to ASTM E18, ANSI (NCSL) Z540-1, (ISO) 10012-1, ISO/IEC 17025, ISO 6508 Lifetime Guarantee Highest quality steel, brass and aluminum Rockwell test block surface hand lapped and diamond polished to a mirror .The previous NIST investigations examined how much a 9 mm thick test block will bend due to repeated indentations and how the bending affects the measurement results. That examination was made by performing Rockwell B hardness tests over the surface of a brass test block, and periodically measuring the flatness of the block’s bottom surface.All Wilson Rockwell hardness test blocks are calibrated in the Wilson Hardness Calibration Laboratory in Binghamton, NY. The Wilson lab is accredited to ISO/IEC 17025 by A2LA and the testers used in the calibration process undergo a stringent monitoring process using NIST traceable devices. . We work directly with the steel and brass mills to .

ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your application.Rockwell Hardness Test Blocks (Brass) Part No. Description Shape Range Comments 900330-9414BH Rockwell B Square 80’s Made in USA 900330-9414BL Rockwell B Square 50’s Made in USA Phase II offers a vast array of different hardness test blocks for Rockwell, Brinell and Vickers scales, as well as Portable hardness testers Phase II hardness test .

does hard rock ac drug test

Rockwell testing falls into two categories: Regular Rockwell testing (e.g., C and B scales) and Rockwell superficial testing (e.g., 30 N and 30 T scales). High Rockwell hardness numbers represent hard materials and low numbers soft materials. d 2 www.wilsoninstruments.com Fundamentals of Rockwell Hardness Testing As part of a project to produce primary hardness reference blocks for the Rockwell B hardness scale at the National Institute of Standards and Technology (NIST) . J. (2003), Effects of Bending in Brass Rockwell B Scale Test Blocks, IMEKO TC (Accessed October 11, 2024) Additional citation formats Google Scholar; BibTeX; RIS;Please contact us here: 1- 888-400-4243 (USA & Canada) 1-631-321-0160 (International) WESTport Corporation 510 Montauk Highway West Islip, NY 117955.2.1 There are two general classifications of the Rockwell test: the Rockwell hardness test and the Rockwell superficial hardness test. 5.2.2 In the Rockwell hardness test the preliminary test force is 10 kgf (98 N). Total test forces are 60 kgf (589 N), 100 kgf (981 N) and 150 kgf (1471 N). In the Rockwell superficial

Here are the most popular methods for testing the hardness of brass in the industry. Rockwell Hardness Test; Rockwell hardness test method utilizes a Rockwell hardness testing machine equipped with either a tungsten carbide ball indenter or a diamond indenter. For the ball indenter, four different sizes exist, while the diamond indenter only .Rockwell Hardness Test Blocks (Brass) Part No. Description Shape Range Comments 900330-9414BH Rockwell B Square 80’s Made in USA 900330-9414BL Rockwell B Square 50’s Made in USA Phase II offers a vast array of different hardness test blocks for Rockwell, Brinell and Vickers scales, as well as Portable hardness testers Phase II hardness test .B36/B36M Specification for Brass Plate, Sheet, Strip, And Rolled Bar B96/B96M Specification for Copper-SiliconAlloy Plate, Sheet, Strip, and Rolled Bar for General Purposes and Pressure Vessels . hardness indenters, and for the standardization of Rockwell hardness test blocks. The standardizing machine differs from a regular

Buehler's industry leading hardness testing blocks ensure accuracy, integrity, and traceability in hardness testing processes. The comprehensive range of scales and blocks, associated with Rockwell, Brinell, Vickers and Knoop testing.

well hardness test blocks. The standardizing machine differs from a regular Rockwell hardness testing machine by having tighter tolerances on certain parameters. 3.1.7.3 portable Rockwell hardness testing machine a Rockwell hardness testing machine that is designed to be transported, carried, set up, and operated by the users, and that measures .

Steel: Steel is a common material for hardness test blocks and is often used for Rockwell hardness testing. The blocks can be made from a range of different steel alloys, such as SAE 4130, which has a known .

Hardness testing blocks are designed for metals hardness testers calibration. There are available different standard nominal values of the blocks, such as: 25 HRC, 45 HRC, 65 HRC, 90 HRB, 83 HRA. Basically, the blocks are made .

Hardness Test Block, Rockwell Hardness Test Blocks , Leeb Hardness Test Blocks, Portable hardness test blocks, Vickers hardness test blocks . Rockwell Hardness Test Blocks (Brass) Part No. Description Shape Range Comments; 900330-9414BH: Rockwell B: Square: 80’s: Made in USA: 900330-9414BL: Rockwell B: Square: 50’s:Hardness Test Blocks and Accessories/Rockwell Hardness Test Blocks/Brinell Hardness Test Blocks/Vickers Hardness Test Blocks/Portable Hardness Test Blocks/Leeb Hardness Test Blocks Please contact us to ensure the part is NOT discontinued prior to ordering. . Rockwell Hardness Test Blocks (Brass) Part No. Description Shape Range Comments .Rockwell Standard Hardness Test Block Suppliers. Conduct regular accuracy checks with your Ames test blocks. This is the standard Brass Test block. part number T-1192. Additional information. Weight: 1.00 lbs: Dimensions: 6 × 3 × 3 in: Reviews There are no reviews yet.The Rockwell hardness test continues to be applied as a tool for assessing the properties of a product while the tolerances on the acceptable material . HRB measurement value for brass test blocks at three hardness levels. ... 81 Table of Contents. Figure B.7 Relationship between the recovery dwell time and the .

E 5 H – H STD (2) where: H = average of n hardness measurements H 1, H 2,.,H n made on a standardized test block as part of a performance verification, and H STD = certified average hardness value of the standardized test block. 3.2.3 The repeatability R in the performance of a Rockwell hardness machine at each hardness level, under the particular verification .

Calibrated to ASTM E18, ANSI (NCSL) Z540-1, (ISO) 10012-1, ISO/IEC 17025, ISO 6508 Lifetime Guarantee Highest quality steel, brass and aluminum Rockwell test block surface hand lapped and diamond polished to a mirror finish Superior accuracy and ease of testing for the operator Special heat treat process insures maximuHardness testing blocks are designed for metals hardness testers calibration. There are available different standard nominal values of the blocks, such as: 25 HRC, 45 HRC, 65 HRC, 90 HRB, 83 HRA. Basically, the blocks are made from Carbon Steel, but also available blocks are made from Brass and Aluminium.5 Benefits of using Ames Portable Rockwell Hardness Testers; . Brass Test Block $ 169.70 Add to cart; Hard Steel Test Block $ 169.70 Add to cart; . Search. Cart. Tagged With32.6, 4812, anvils, for nanp particles, hr30tw, laser distance meter, portable hardness tester, t-1170 30, test block, thermal camera . Proudly powered by WordPress .

Rockwell Hardness Test Blocks (Brass) Part No. Description Shape Range Comments 900330-9414BH Rockwell B Square 80’s Made in USA 900330-9414BL Rockwell B Square 50’s Made in USA Phase II offers a vast array of different hardness test blocks for Rockwell, Brinell and Vickers scales, as well as Portable hardness testers Phase II hardness test .Rockwell Regular Test Blocks – With Certification Made to order. Specify hardness range (3 below and 3 above target) at check out. The XX represents a variable part number that follows the following example: A C scale 55 hardness C Diamond 150 Kg Steel would have the following part number RC1052-58.. We offer an extensive Rockwell Hardness Test Block selection All of .

Empréstimos do Banco do Povo de Birigui tiveram aumento .

rockwell hardness test blocks brass|hra vs hrc